Whisk™

ESS Whisk™

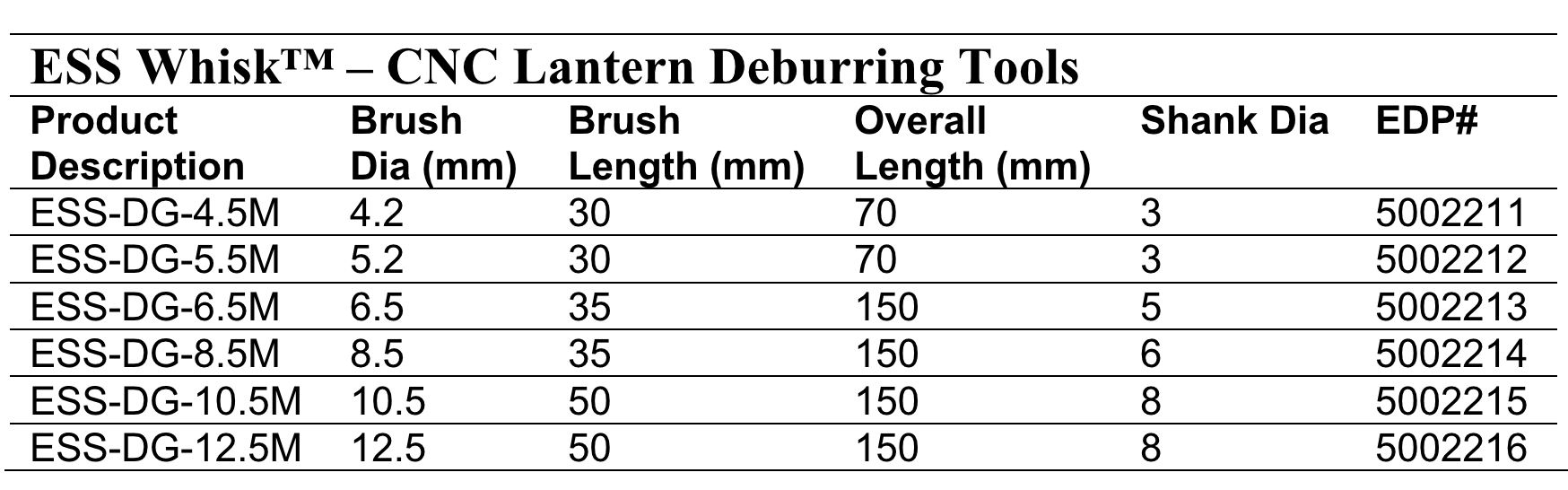

CNC Lantern Deburring Tools

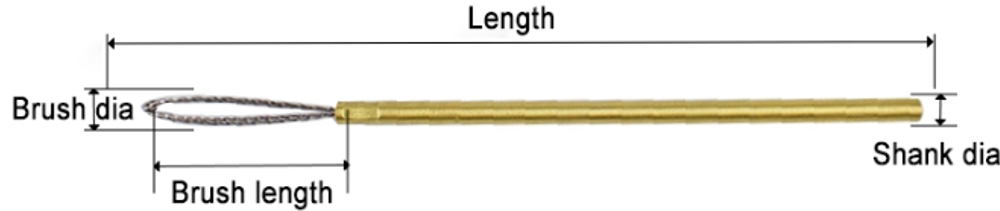

ESS Whisk™ deburring tools are engineered for CNC equipment, robotic cells, and precision finishing systems that require gentle yet effective edge refinement.

These tools use a flexible radial brush cluster (“lantern” style) designed to conform to complex contours and edges, removing fine burrs without rounding edges excessively.

Why ESS Whisk™

Adaptive filament “whisk” design follows part geometry

Excellent for cross-hole edges, slots, grooves, and intersecting features

Maintains part accuracy — no aggressive edge roll-off

Ideal for

precision machined metals, medical components, aerospace parts, and automotive valve/port edges

Best For:

- Fine burrs, micro-burrs, and edge polish requirements in:

- Hardened alloys

- Aluminum & stainless

- Titanium & nickel alloys

- Tool steels

Features & Applications

Looking for more? Browse the catalog

Download and browse the entire catalog, click below for our geometric offering.