Bloom™

ESS Bloom™

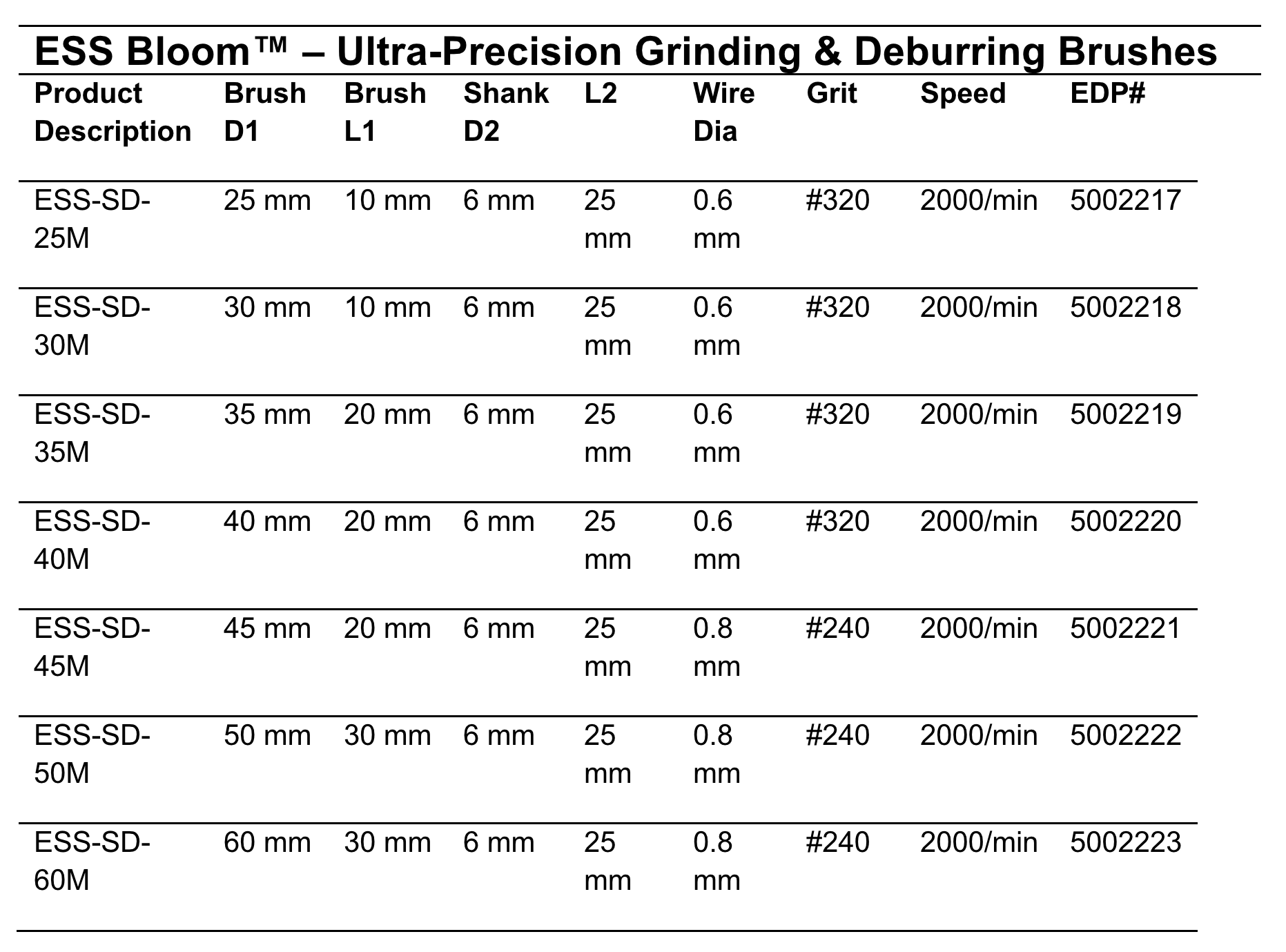

Ultra-Precision Grinding & Deburring Brushes

What it is

ESS Bloom side-polishing brushes are ultra-precision deburring and finishing tools for CNC machines, robots, and benchtop equipment. They use uniform alumina-abrasive filaments that cut consistently without gouging, leaving a bright, smooth finish—even on delicate features.

Why Bloom

- Mirror-ready finish: Produces a shiny, smooth surface (target roughness to ~Ra 0.1 with proper parameters).

- Fast, consistent burr removal: Dense, evenly distributed filaments deliver high grinding force and long life, clearing light burrs quickly.

- Process-safe on geometry: Non-metal alumina filaments won’t scratch or deform edges; no folded metal or tears.

- Broad application window: Ideal for side faces, threads, inner holes, and small edge burrs (≈≤0.2 mm).

How to run

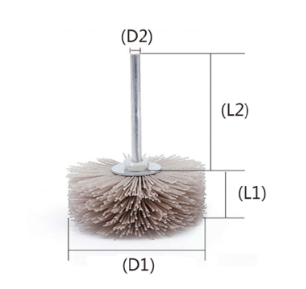

- Chuck the 6 mm shank in the spindle or toolholder.

- Program speed/feed and light radial contact.

- Traverse the brush across the face; reciprocate as needed for uniform finish.

Specs & Applications

Looking for more? Browse the catalog

Download and browse the entire catalog, click below for our geometric offering.