Contact™

ESS Contact™

Surface Deburring & Polishing Brush

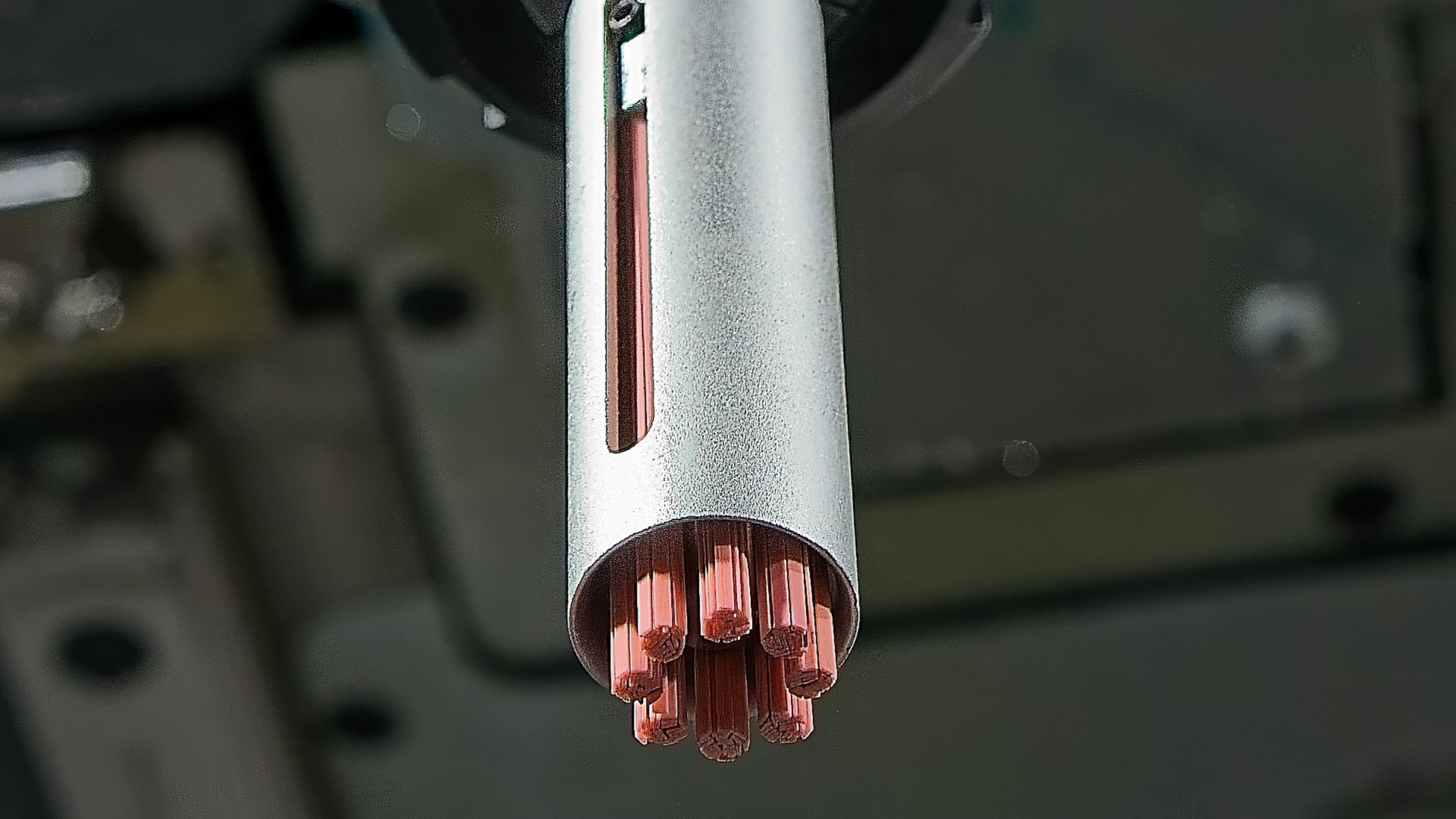

ESS Contact™ is a high-precision surface deburring and polishing brush designed for CNC machines, robots, and automated finishing equipment. Built with ultra-fine ceramic-fiber abrasive filaments, it offers effective burr removal and surface prep while maintaining tight tolerances and preventing damage to the substrate. (Source: original product page)

Process Guidelines

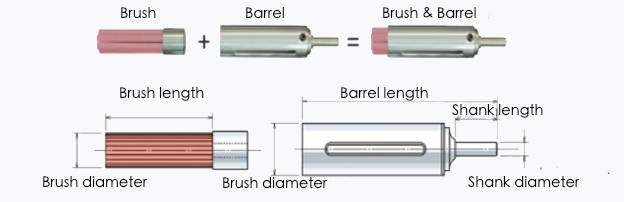

- Mount the ESS Contact™ brush in the machine spindle or collet holder; ensure the Barrel or shank is properly secured.

- Program the machine with appropriate speed and feed—typical example from source: ~5000 min⁻¹ for a small diameter brush in stainless steel, ~5 s process time.

- Engage the brush head with light contact and perform reciprocating or walking strokes across the surface to uniformly remove burrs and polish.

- Use coolant, air blow-off, or lubrication as needed; avoid dwelling too long in one spot to maintain tool life and surface integrity.

Benefits at a Glance

- Superior finish quality: Achieves smooth, shiny surfaces with minimal rework

- Precision integrity: No rounding of edges, no unexpected material removal

- Automation-friendly: Adapted for CNC, robot cells, and automated finishing operations

- Material flexibility: Works across a broad range of metals and machined parts

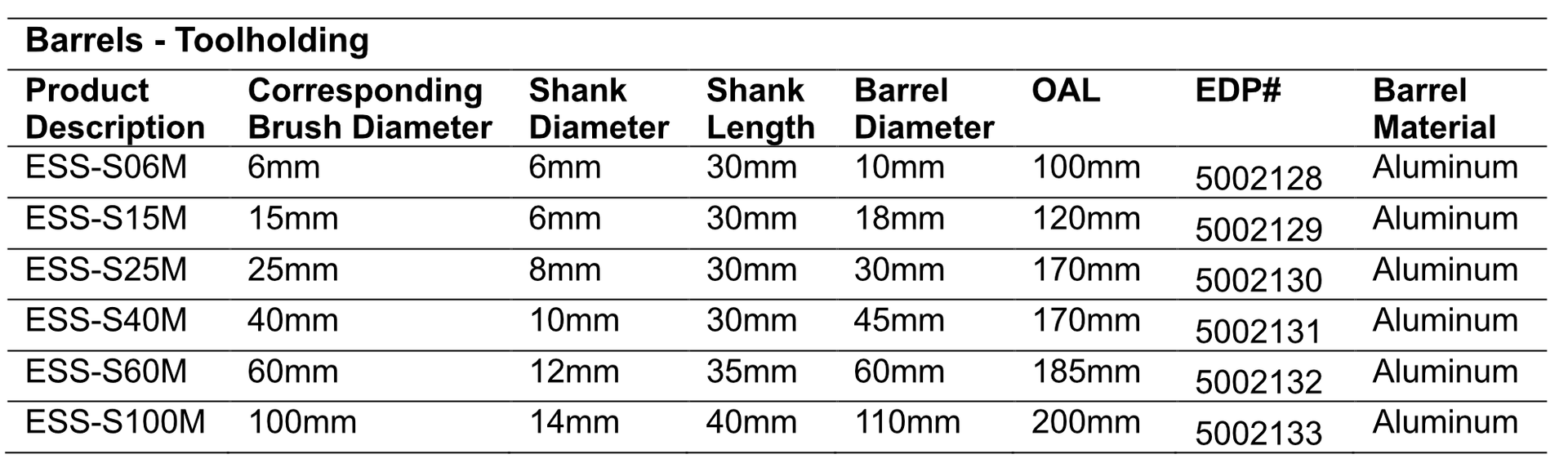

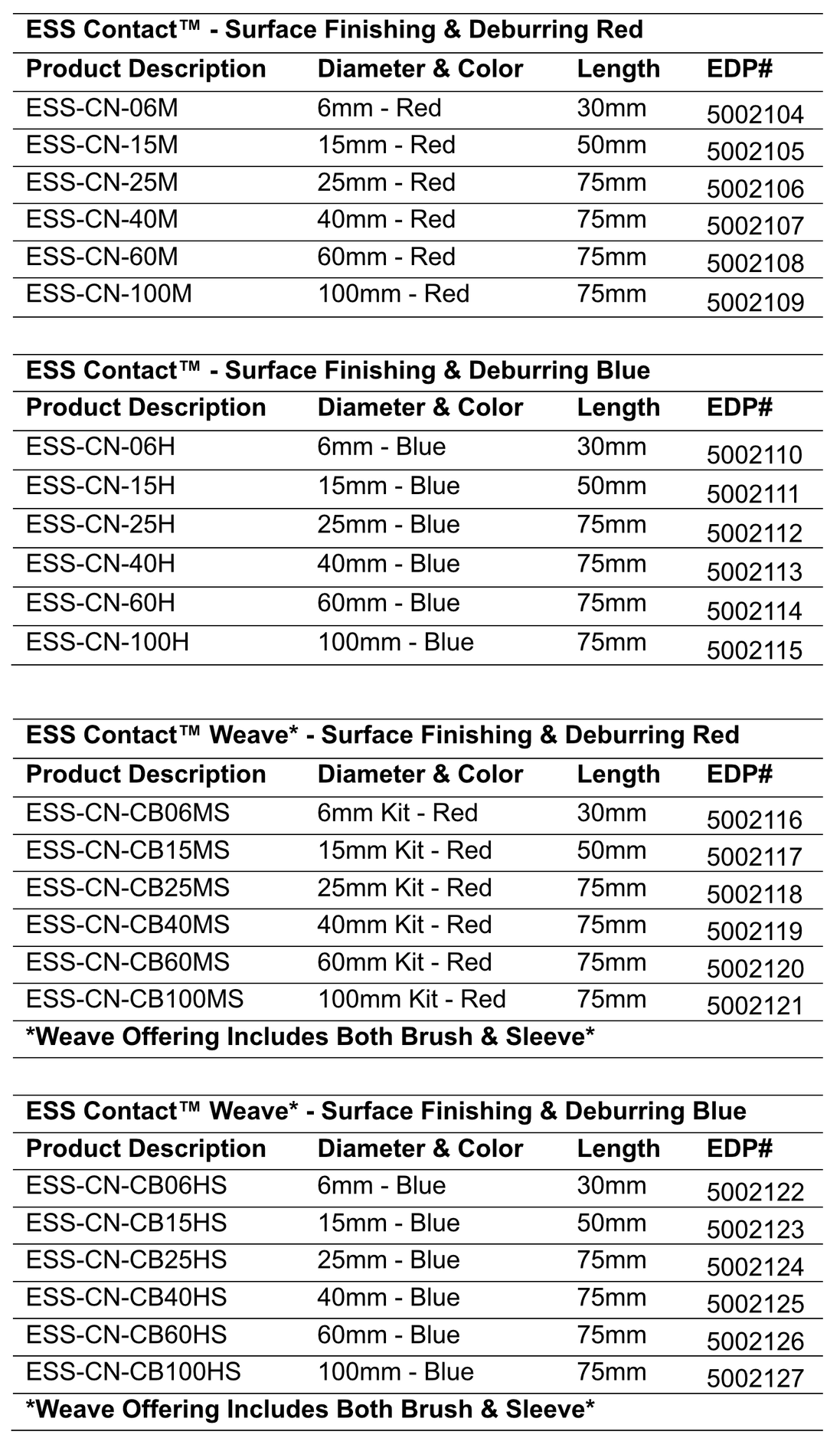

Available Sizes & Options

The product line supports a wide range of diameters (e.g., starting from 1 mm, 1.5 mm, 2 mm, etc) and is color-coded for material/hardness (for example, pink for soft metals like aluminum/copper, blue for harder metals like stainless/iron) in the original naming.

Custom sizes, grits, and brush configurations are available upon request.

Features & Applications

Looking for more? Browse the catalog

Download and browse the entire catalog, click below for our geometric offering.