Stoned™

ESS Stoned™

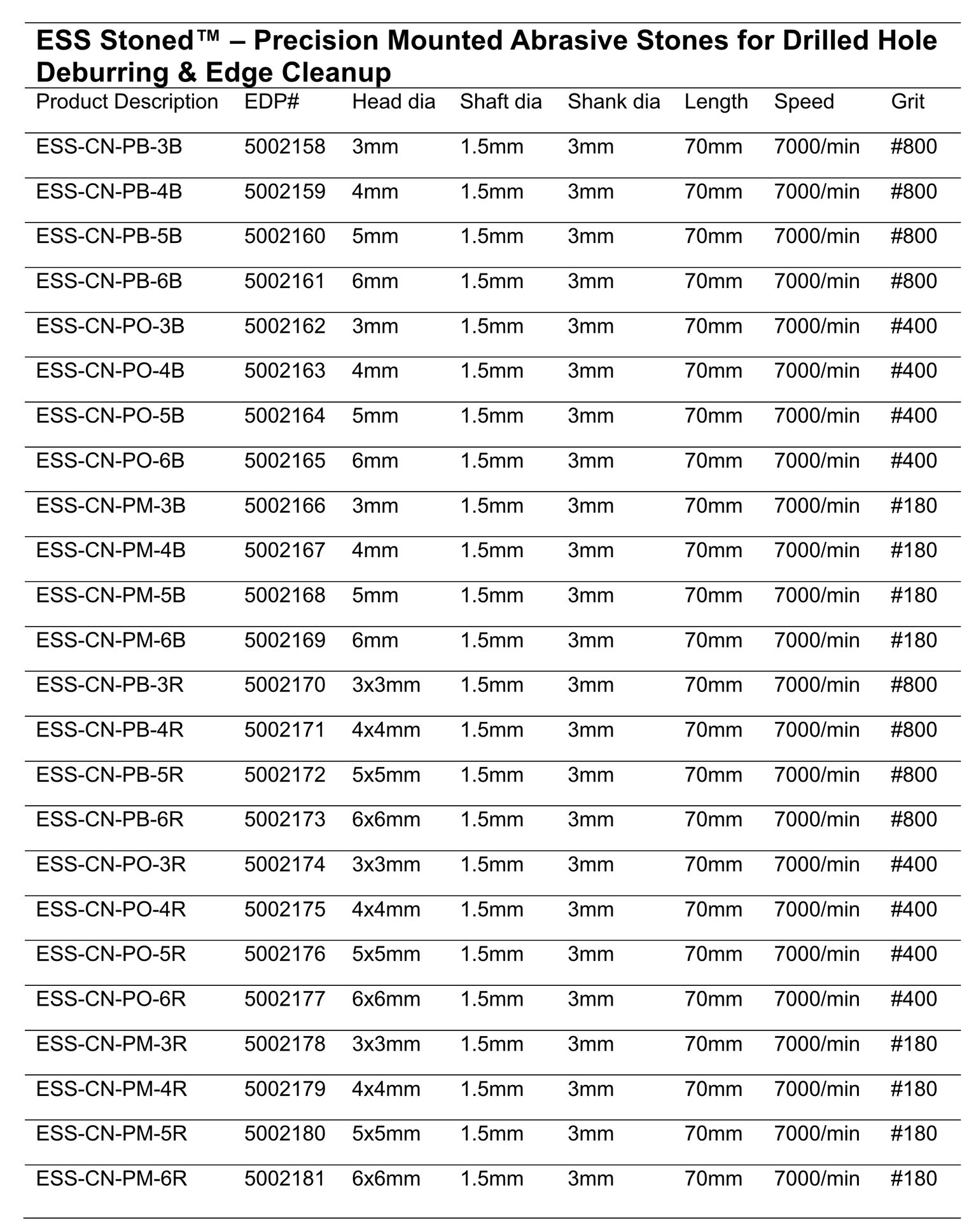

Precision Mounted Abrasive Stones for Drilled Hole Deburring & Edge Cleanup

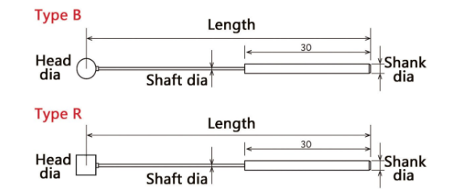

The ESS Stoned™ series is built around a ceramic-fiber oil-stone / mounted abrasive point structure designed for high-precision internal hole and port deburring, chamfering, and edge blending applications. According to the original manufacturer’s description, the tool uses “developed ceramic fiber oil stone” technology suitable for removing burrs from edges of holes and cross-holes with minimal impact on part geometry.

Typical Performance Metrics

- Example: 6 mm brush at ~5,000 rpm achieved clean finish in ~3 seconds in stainless steel.

- Burr root size target: below ~0.1 mm for optimum performance.

How to Use & Processing Tips

- Secure the tool handle in a machine spindle, collet or appropriate holder.

- Set appropriate speed and feed (manufacturer example: ~5,000 to 7,000 rpm for certain diameters) and program a light radial contact, reciprocating or helical motion as needed.

- For cross-hole cleanup: engage and walk the tool across the intersection to remove burr root; avoid dwelling at one spot.

- Provide coolant or lubrication if required; maintain stable contact without excessive pressure to minimize tool wear and avoid part damage.

- Observe maximum speed and tool usage guidelines. The source warns that “breakage occurs when used beyond the maximum rotational speed or used with a pneumatic tool.”

Grit & Material Designation

- #800 (Blue): For softer metals (aluminum alloy, copper, brass).

- #400 (Orange): For moderate-hardness metals.

- #180 (Yellow): For harder metals (stainless steel, iron, die-castings).

With ESS Stoned™, you get a robust, high-precision internal-hole deburring/finishing tool capable of handling cross holes and tight geometries while maintaining surface integrity and dimensional control. It’s ideal for high-volume automated cells, precision components, and materials ranging from aluminum to stainless.

Features & Applications

Looking for more? Browse the catalog

Download and browse the entire catalog, click below for our geometric offering.