SiC Ball Hone™

ESS SiC Ball Hone™

Internal Bore Deburring & Finishing

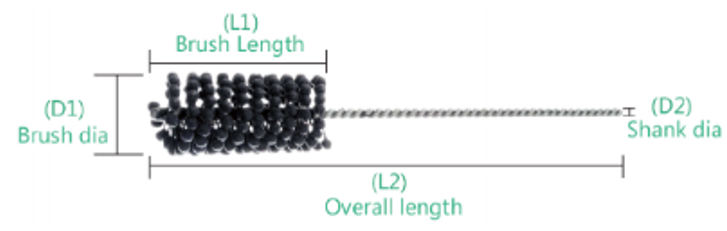

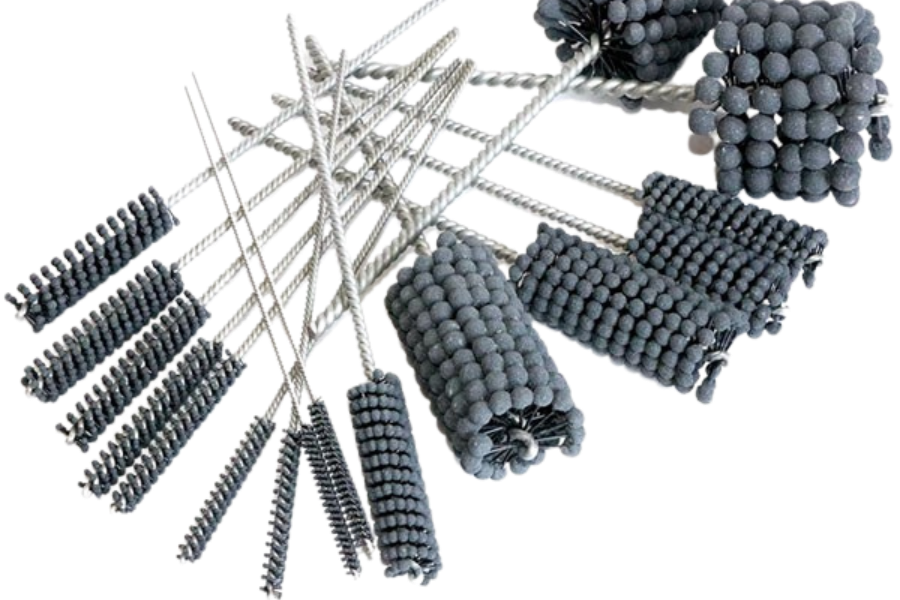

ESS SiC Ball Hone™ tools are flexible, spherical-tip abrasive brushes designed to finish and deburr the inside of bores, tubes, ports, and cross-holes. Silicon-carbide–impregnated filaments conform to minor bore irregularities to produce a controlled plateau finish without altering size.

Highlights

- Conforming “ball” tips blend edges at intersections and cross-holes

- SiC abrasive cuts efficiently on cast iron, steel, stainless, aluminum

- Produces a uniform plateau finish that improves lubrication and wear-in

- Prevents sharp edges and micro-burrs; protects dimensional accuracy

- Runs in CNCs, drill presses, hand tools, or robotic cells with coolant.

Use & Setup

- Select a hone slightly larger than bore ID for proper contact

- Use low–medium RPM with light stroke; keep tool and bore lubricated

- Short, even reciprocation; avoid dwelling in one location

- Ideal for hydraulic/pneumatic passages, engine components, valve bodies, medical and aerospace fittings

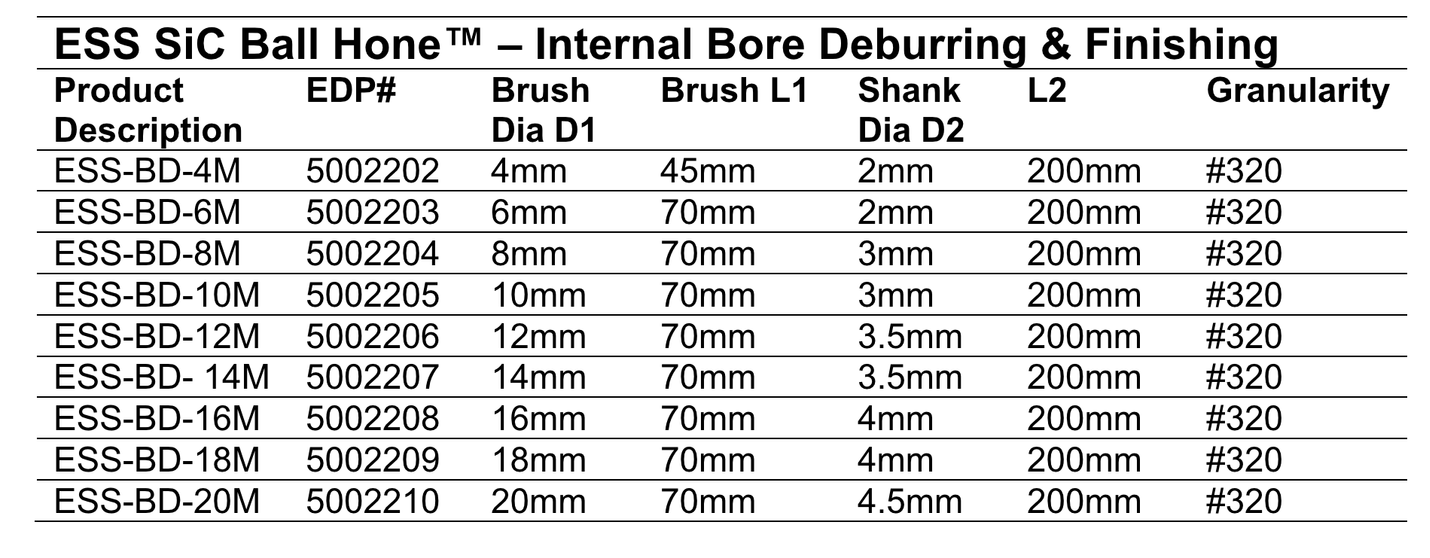

Customization available: grits #80 – #800, brush diameters 3–300 mm, lengths 20–1500 mm. Non-standard sizes: 50-piece minimum.

Features & Applications

Looking for more? Browse the catalog

Download and browse the entire catalog, click below for our geometric offering.